- Case Study

How Voyager Became Equinor's Maritime Operations Hub

Industry

Oil and Gas,

Wind

Module

Voyage Management

Key User

Supply Chain & Logistics

Before, Equinor coordinated rig movements manually, with a high risk of human error and no reliable records of historical information.

Now the supply chain and logistics team has support over the planning and execution phases, letting Voyager manage all the checklists, operational processes and document handling.

Key Benefits

> Centralized Planning

> Enhanced Efficiency in Rig Moves

> Better Vessel Selection

The Voyager Approach

Voyager became Equinor’s maritime operations hub, supporting the company’s transition from fossil fuels to renewable energies and overseeing both the rig move and offshore wind activity.

Features Onboarded

RIG MOVE AND OFFSHORE WIND OPERATIONS FORECAST

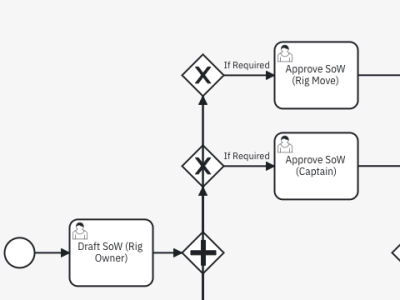

Before, the entire process was managed using excel and emails, which was highly inefficient, not standardized and very difficult to audit.

Now, a series of automated workflows capture all the relevant information from the initial schedule to the summary of each Operation.

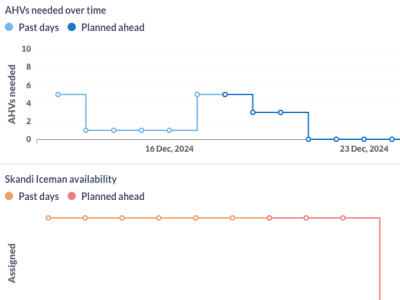

VESSEL AVAILABILITY AND SPOT RATES VISIBILITY

Without clear operational KPIs it’s impossible to estimate the cost associated with rig waiting times.

Now Equinor has the data to understand the factors which are behind operational setbacks and vessel availabilitY.

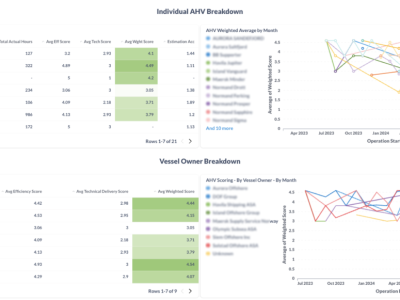

VESSEL PERFORMANCE SCORING

Voyager enables Equinor to objectively score each vessel on the efficiency of each operation.

This allows them to benchmark optimal vessels for specific jobs with a goal of reducing rig move times vs lowest cost/carbon generation.

LOCATION DATA

INTEGRATION

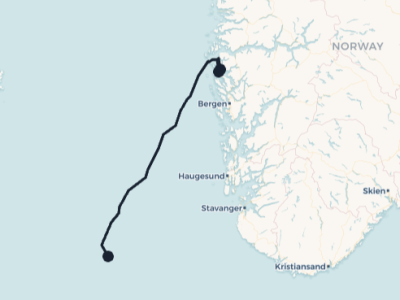

Location data is seamlessly and automatically shared without the need for human input.

The Rig Move team can now visualize operations on a digital map in real-time, making it easier to plan, adjust, and communicate updates.

- Contact Us